-40%

Vapor blasting Service Triumph Norton BSA Motorcycle Vaporblasting

$ 23.76

- Description

- Size Guide

Description

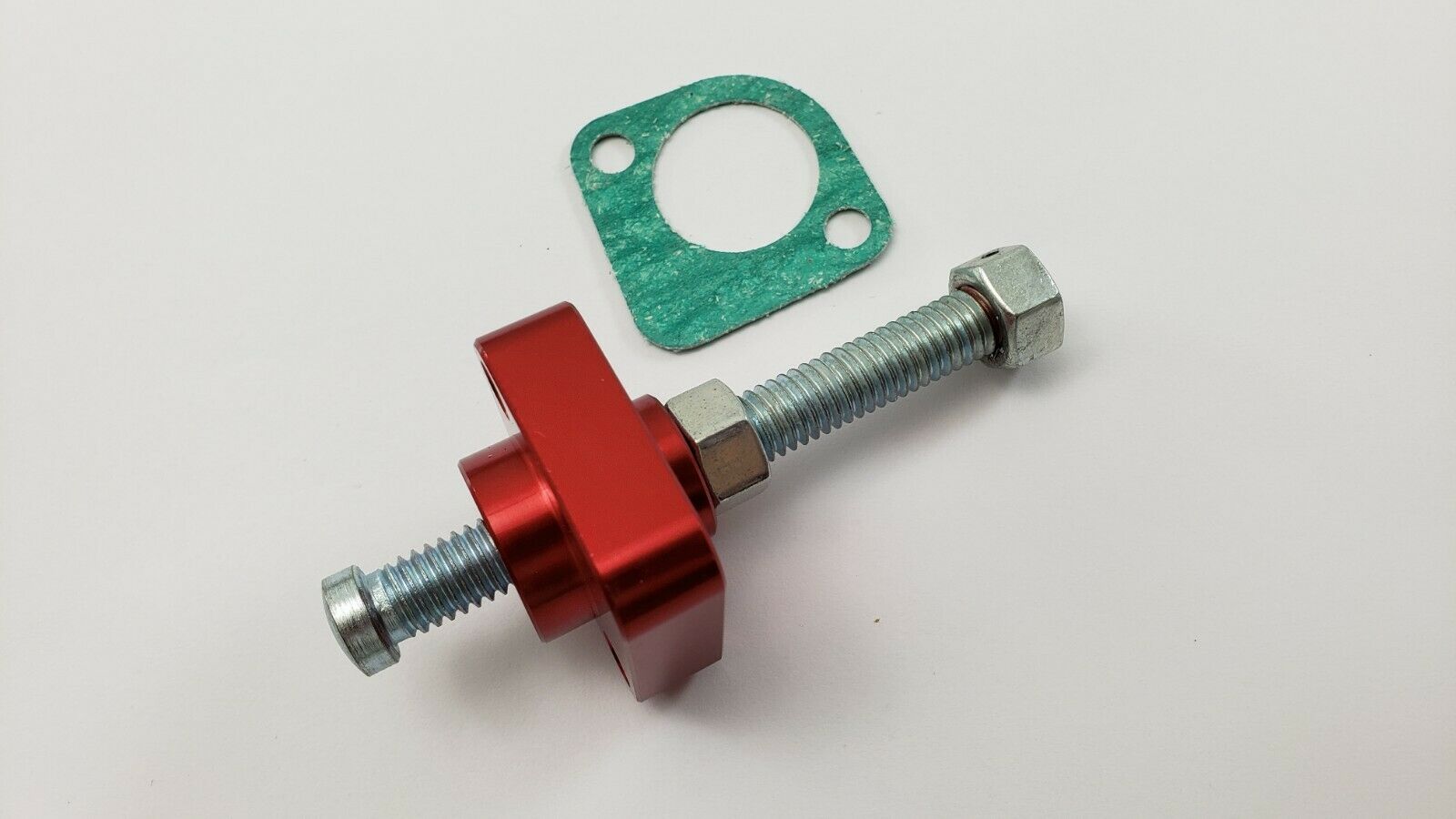

If you are interested in building your own vapor blaster from a regular sand blasting cabinet, go to http://arnoldsdesign.com/Digital-Plans-and-ebooks.html and get the plans and 3D model.I offer quality vapor blasting service at reasonable prices. All work is guaranteed. Go to for more details, information, price quotes and shipping information. Note that this is for a service, and the price shown is typical of a bike carb. Please contact me for a quote at 814 772 5866 for other types of parts and quantities. Please don't click on "Buy it Now". Note: The parts shown in the photos are examples of work done at Arnold's Design and are not for sale. To find me on the web, just google Arnold's design vapor blasting.

What is vaporblasting?

Vapor blasting is a process that was developed during the second world war. It was initially used in industry to create surface tension in parts to strengthen them. Rolls Royce used it to strengthen turbine blades before assembly into jet engines. It is also referred to as liquid honing, or wet blasting. It is quite popular there for bike restoration. The process uses water, beads, mild cleaners, rust inhibitor, and air. These are mixed into a slurry and propelled at high speed toward the surface of a metal part, such as aluminum, brass, as well as mild steel. It seals the surface, resulting in cosmetic enhancement and imparts a micro finish that helps it resist further staining and oxidation. The water component of the slurry provides a hydraulic cushioning effect to soften the bead's impact on the metal's surface. Working together, they provide a gentle, and somewhat time consuming process that peens the metal surface and leaves a bright lustrous satin finish. Finishes vary from alloy to alloy and manufacturer to manufacturer, but all are good. Aluminum castings in particular are well suited to this. I take a lot of pride in these finishes. We use a three step process to do this. It took a good deal of time and effort to refine this process to the point where I felt it was good enough for customer's parts. I want to maintain a good reputation, plus I'm a bit of a perfectionist.

How much does it cost?

Make sure the parts are free of dirt, oil, grease, baked on oil, and grime. I used to clean parts here, but it literally takes me hours of work in some cases, especially anything with fins, and inside corners. So, before you ship it, make sure it is really clean.

For a price quote, go to my website and email me or message me here. My work is guaranteed. I follow the golden rule. I treat you as I would want to be treated myself, and pledge to do my best work on your parts. If ever you are not satisfied with the finish I provide, let me know within 30 days, and I will return your money and shipping expenses. Thank you.